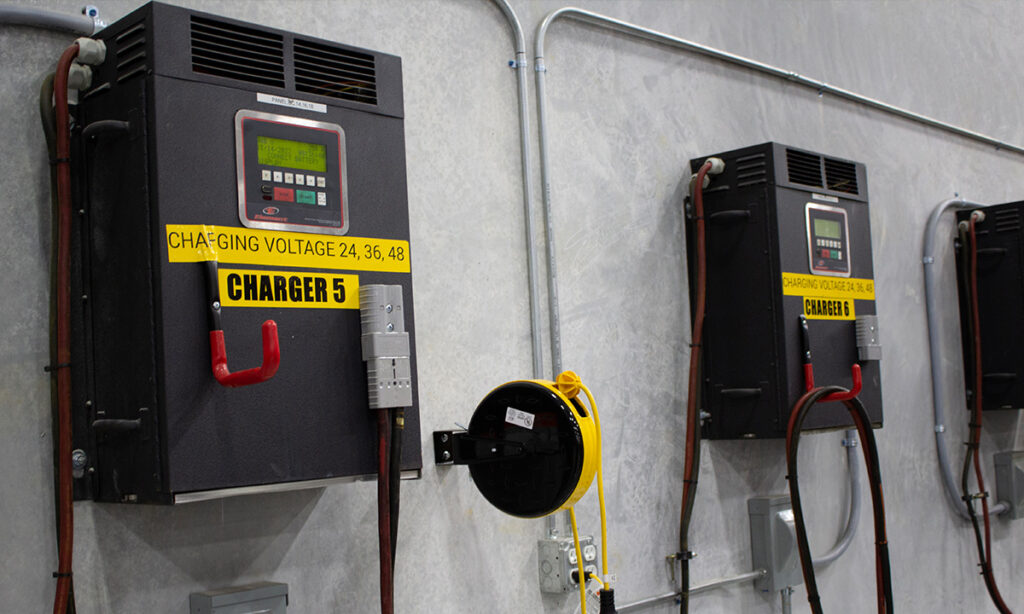

Chargers

Charger Technology

When it comes to deciding what kind of battery you are going to use for your material handling fleet.

Think deeper when it comes to deciding what kind of chargers you are going to use for your material handling fleet. There are different types of chargers that perform well in various operations and charge cycles.

Conventional

Conventional charging is the simplest and, consequently, has the lowest infrastructure cost. To charge conventionally, all it takes is eight hours of continuous charging followed by a required eight-hour cooldown period.

- Most common

- 8x8x8 Charge Cycle

- Ideal for single shift operations

- Require dedicated charging areas to contain hazards such as spills leaks, discharge of toxic gases

Fast Charging

Fast-charging is great for multi-shift and 24/7 operations, the trade-off is infrastructure cost. As the name suggests, the charge rate is significantly faster and the lift is charged more frequently throughout the day.

- Not recommended for lead acid batteries

- Typically used in Lithium-ion fleets

- Ideal for multi-shift operations

- 10-30 minute charge times

- No cool down required

Opportunity Charging

Running a two-shift operation? Then maybe opportunity charging is the best option for you. Opportunity charging is done during short periods of time in which the battery is not being used.

- Typically used in low internal resistance batteries

- Ideal for multi-shift operations

- Ability to utilize sporadic charges during lunch breaks or lower vehicle usage intervals

- Easier to integrate with existing electrical infrastructure